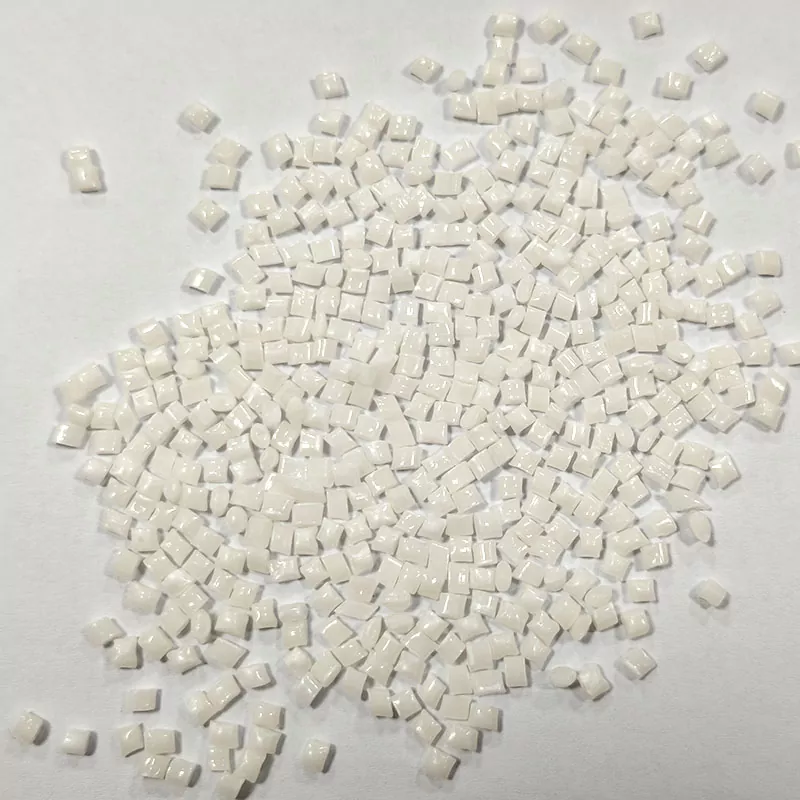

Welcome to Accom Advanced Materials Technology Co., Ltd., a specialized manufacturer of Engineering Plastic Pellets. We focus on providing high-performance, durable plastic solutions. Leveraging years of industry experience and technological innovation, Accom® has earned a stellar reputation globally. Our engineering plastic pellets not only possess superior mechanical properties and thermal stability but also cater to various complex application needs. Whether you require small trial batches or large-scale purchases, Accom® is dedicated to offering you the best product experience and support services, helping you stand out in the competitive market.

Accom®'s Engineering Plastic Pellets find extensive applications in automotive manufacturing, electronics and electricals, construction, and aerospace. These pellets are characterized by:

High Strength and Toughness: Suitable for manufacturing components that need to withstand high loads and impact forces.

Excellent Thermal Stability and Chemical Resistance: Maintaining performance stability under extreme temperatures and corrosive environments.

Ease of Processing: Compatible with various molding techniques such as injection molding and extrusion, ensuring efficient production.

Customized Solutions: Offering different specifications of engineering plastic pellets according to customer needs, such as enhanced, flame-retardant, or anti-static types, tailored to specific scenarios.

For companies seeking high-quality materials, choosing Accom®'s engineering plastic pellets can enhance product quality and reliability while effectively reducing production costs and boosting market competitiveness. Particularly in demanding applications like automotive engine parts, electronic connectors, and industrial gears, our engineering plastic pellets are favored for their superior performance.

At Accom®, we adhere to high standards of quality management. All produced engineering plastic pellets comply with ISO 9001 quality management system certification and multiple international environmental standards such as RoHS and REACH. This underscores our commitment to product quality and environmental responsibility. Our products have been successfully exported to numerous countries and regions, establishing long-term partnerships with several Fortune 500 companies. Accom® boasts an in-house R&D center and skilled technical team committed to continuous innovation, developing new products that align with market demands. We place significant emphasis on after-sales service, offering one-stop support from pre-sales consultation to post-sales technical assistance, ensuring a worry-free experience for our customers.

By choosing Accom®, you choose health, safety, and quality. We will continue to strive for excellence, delivering superior products and services, and driving the industry forward together. Through relentless technological innovation and service optimization, Accom® aims to become one of the most respected global suppliers of engineering plastic pellets, committed to creating more value for our customers and playing a leading role in the global market.

Copyright © 2024 Suzhou Accom New Material Technology Co., Ltd. All Rights Reserved.