After 20 years of working in the materials industry, I have witnessed too many products fail in the market due to insufficient material performance. Last year, I was impressed by a case of a home appliance brand in Guangdong - after they adopted Accom® Highly Toughened Polypropylene, the product drop test pass rate increased from 65% to 98%, which made me more convinced of the importance of material innovation to product competitiveness.

When I visited a daily necessities manufacturer in Zhejiang last month, their R&D director showed me a set of comparative data: when using traditional PP materials, the product return rate was as high as 7%; after switching to Accom® Highly Toughened Polypropylene, the return rate dropped to less than 1%. This is due to our unique molecular structure design, which increases the material impact strength by more than 300%.

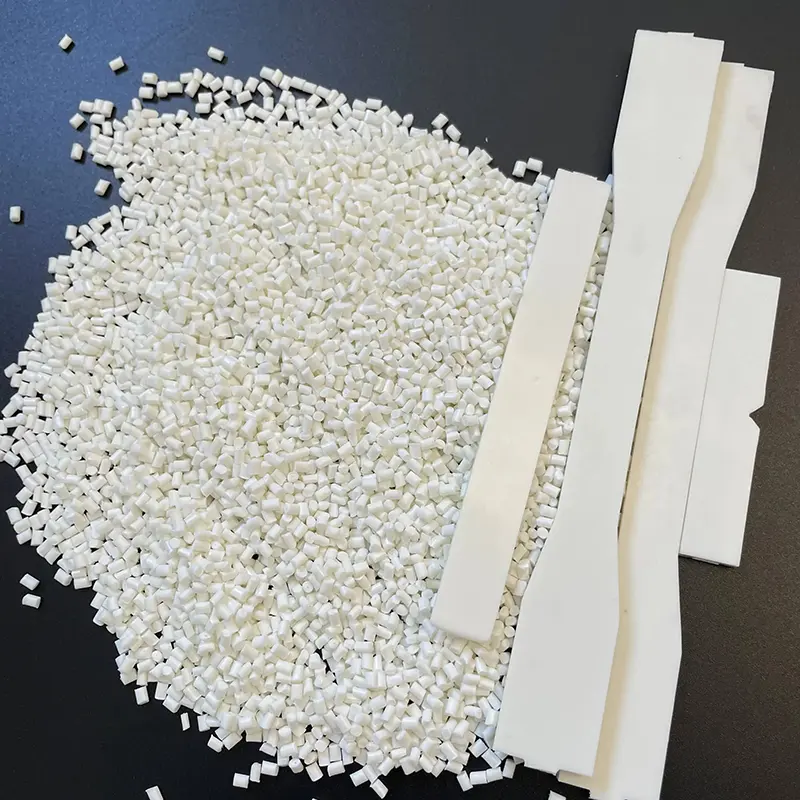

Through the experience of serving hundreds of manufacturing companies, I have summarized three core parameters: first, impact strength, our Highly Toughened Polypropylene can reach 80kJ/m²; second, flexural modulus, maintained at an excellent level of 1500MPa; and finally, low temperature resistance, which still maintains good toughness at -30℃.

The quality manager of an international automotive parts supplier shared an important discovery: since adopting our Highly Toughened Polypropylene, not only has the qualified rate of parts increased significantly, but more unexpectedly, it has obtained the first-tier supplier qualification of a German car company. This proves that material performance directly affects the market competitiveness of enterprises.

When I recently did a material evaluation for a tool manufacturer in Jiangsu, I found that the brittle cracking problem caused by the ordinary PP material they used caused millions of yuan in after-sales losses every year. Each batch of Accom® materials undergoes rigorous performance testing to ensure that customers can provide stable and reliable material solutions.

The new product case of a high-end home brand in Shandong is very convincing. After they chose Accom® Highly Toughened Polypropylene, the product was still in short supply in the European and American markets at a 30% premium. If you are looking for a breakthrough in materials, our technical team is always ready to provide you with professional support.

Our products are very reliable. If you have any needs, please feel free to contact us. We will provide you with efficient solutions online 24 hours a day.

Copyright © 2024 Suzhou Accom New Material Technology Co., Ltd. All Rights Reserved.