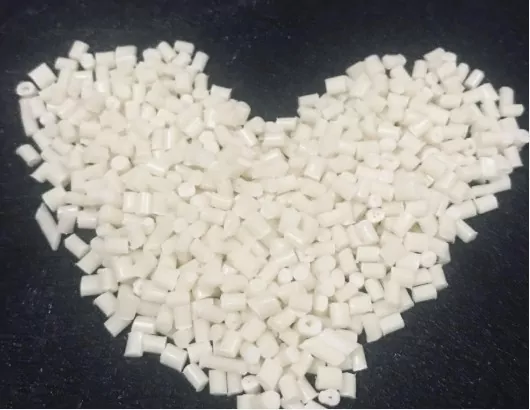

Polyamide 612, a thermoplastic material belonging to the nylon family, has been garnering significant attention in recent industry news due to its unique properties and diverse applications. This material, often abbreviated as PA 612, is a copolymer synthesized from specific precursors, inheriting nearly unchanged characteristics that are highly valued in PA 12 parts.

In terms of material properties, Polyamide 612 demonstrates outstanding resistance to fuels, lubricants, greases, oils, and most industrial solvents. This robust chemical resistance makes it an ideal choice for applications where exposure to harsh chemicals is common. Furthermore, its thermal stability and mechanical strength contribute to its use in high-performance components across various industries.

The nylon industry, which includes Polyamide 612, has been experiencing rapid growth, fueled by innovations in material science and increasing demand from end-use markets. Polyamide 612, in particular, has found niche applications in sectors such as automotive, aerospace, electronics, and medical devices. In the automotive industry, its lightweight properties and resistance to high temperatures make it suitable for engine components, electrical connectors, and piping systems. Aerospace applications benefit from its durability and corrosion resistance, while the electronics sector values its electrical insulation properties.

Moreover, the medical industry has also embraced Polyamide 612 for its biocompatibility and ability to withstand sterilization processes. Surgical sutures, artificial blood vessels, and infusion tubes are among the medical devices that utilize this material.

Recent industry news has highlighted advancements in the production of Polyamide 612, with a focus on improving sustainability and reducing environmental impact. Manufacturers are exploring bio-based raw materials and recycling technologies to create more eco-friendly versions of this nylon. These efforts aim to align with global trends towards circular economy and reduce the carbon footprint of plastic production.

In addition, the growing emphasis on material traceability and certification is driving Polyamide 612 producers to adopt stringent quality control measures and comply with international standards. This ensures that the material meets the safety and performance requirements of end-users, enhancing its credibility in the market.

As the demand for high-performance materials continues to rise, the future of Polyamide 612 looks promising. With ongoing research and development, the nylon industry is poised to uncover new applications and expand its footprint in sectors that demand durability, reliability, and sustainability.

Polyamide 612 is a versatile material with a bright future in the nylon industry. Its combination of chemical resistance, thermal stability, and mechanical strength makes it an excellent choice for demanding applications across multiple sectors. As the industry evolves, so too will the uses and benefits of this remarkable thermoplastic.

Copyright © 2024 Suzhou Accom New Material Technology Co., Ltd. All Rights Reserved.