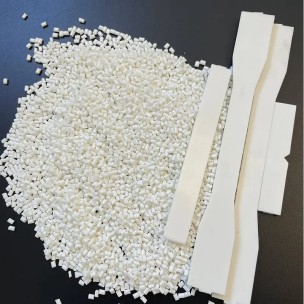

As a widely used basic raw material, polypropylene plastic pellets require a certain amount of storage time in plastic product processing plants, warehouses, and even during transportation. Many users, especially warehouse managers and purchasing personnel, often worry that these pellets will stick together and form clumps over time. While this is possible, it's not guaranteed. The presence and severity of clumping are influenced by a combination of storage conditions and the pellets' own characteristics.

If polypropylene plastic pellets are stored at excessively high temperatures, especially when stored at or above the softening point of polypropylene for extended periods, the pellet surfaces can become relatively soft and sticky. Under these conditions, if pressure is applied between pellets—for example, when stacking too high, placing a heavy load on the bottom pellets, or when packaging bags are stacked too closely together—the pellets can easily stick together, forming hard clumps that are difficult to separate. High temperatures are a key factor contributing to clumping.

Polypropylene plastic pellets are non-polar plastics and are susceptible to static electricity generation during production, transportation, and handling. Particles charged with static electricity attract each other, clinging together like tiny magnets. In a dry environment, this static attraction may only temporarily clumping them together, easily dispersing with a gentle shake. However, if humidity levels are high, or if trace amounts of moisture or other substances are adsorbed on the surface of the particles, this attraction can be exacerbated, leading to actual clumping.

To meet requirements for aging resistance, antioxidant properties, antistatic properties, and coloring, polypropylene plastic pellets are added with various additives during production. Some additives are highly mobile or incompatible. During long-term storage, these additives may release sticky substances, causing adhesion.

If polypropylene plastic pellets are not properly sealed, moisture can easily penetrate. Once the pellets absorb moisture, they can become a "bridge" for adhesion. Furthermore, the packaging bag material, such as whether the inner film is smooth and low-viscosity, as well as the density and height of the stacking, directly affect the pressure the pellets withstand. The greater the pressure, the closer the particles are in contact, and the greater the likelihood of agglomeration under high temperature or sticky surface conditions. Storing in a cool, dry, well-ventilated place and using appropriate packaging can effectively delay the occurrence of agglomeration.

| Critical Control Area | Action Required |

|---|---|

| Temperature | Maintain storage below 40°C |

| Moisture Control | Use moisture sealed containers desiccants |

| Packaging | Select smooth inner lining avoid overfilling |

| Handling | Minimize drop height use anti static equipment |

| Storage Layout | Ensure pallet stability limit stack height |

Copyright © 2024 Suzhou Accom New Material Technology Co., Ltd. All Rights Reserved.