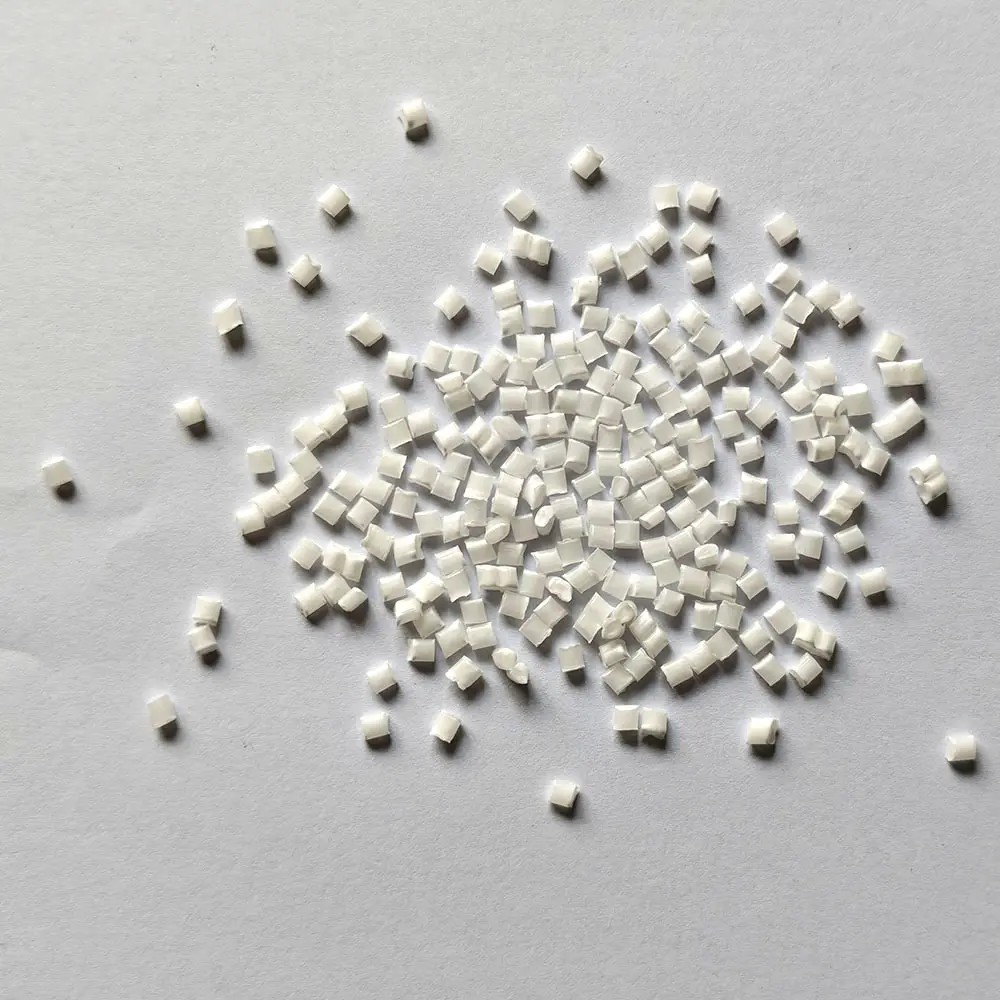

High strength mineral filled polypropylene refers to composite engineering plastics made by modifying polypropylene resin with inorganic mineral particles. Its core features include uniformly dispersed mineral phase, interface bonding system between polymer matrix and filler, and macroscopic performance variation caused by microscopic composite effect.

The essential difference between high strength mineral filled polypropylene and conventional polypropylene is first reflected in the mechanical response level. The rigid particles of mineral fillers form a stress transfer network in the matrix, which significantly improves the elastic modulus and creep resistance of the material. Ordinary polypropylene is prone to plastic deformation under continuous load, while the mineral filling system enhances the dimensional stability of the product by hindering the slippage of molecular chains. The two show opposite characteristics in thermal behavior. Although the addition of fillers increases the heat deformation temperature, the low temperature impact toughness is weakened due to the stress concentration effect.

The change in processing fluidity is due to the interaction between the mineral phase and the melt. High strength mineral filled polypropylene increases the melt viscosity, resulting in an increase in mold filling resistance, while reducing the molding shrinkage rate. The difference in surface properties is that mineral fillers lose the original gloss of pure polypropylene surfaces, present a matte texture and improve adhesion to polar coatings. In terms of environmental tolerance, mineral particles can block the path of ultraviolet penetration and delay the process of photoaging, but the tendency of fillers to settle may affect long-term uniformity.

Copyright © 2024 Suzhou Accom New Material Technology Co., Ltd. All Rights Reserved.