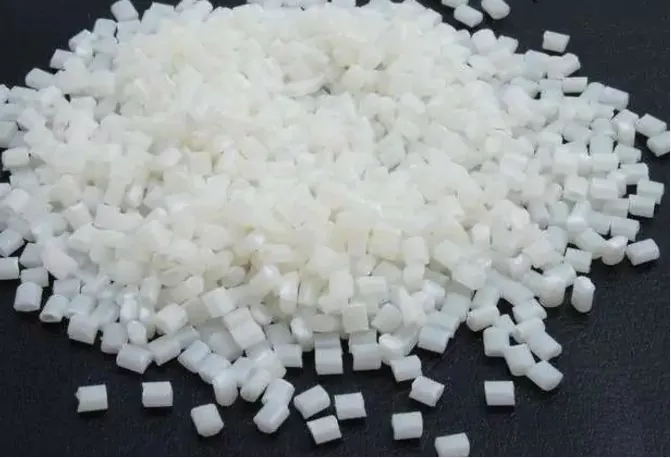

significant attention in the materials science and engineering industries. This advanced material, known for its enhanced durability and mechanical properties, is undergoing continuous innovation to meet the evolving needs of various applications.

One notable advancement is the incorporation of rubber particles into the PA66 matrix, which significantly improves its toughness. Research conducted by Alessandro Pegoretti and Theonis Ricco revealed that the inclusion of rubber particles, such as a random ethylene–acrylic ester–maleic anhydride terpolymer, results in a substantial increase in the essential work of fracture (EWF) parameter. This improvement is primarily attributed to the enhancement of the crack propagation component, while the fracture initiation term decreases with rubber content.

Moreover, studies have investigated the effect of different loading rates on the fracture behavior of PA66 toughened with rubber. It was observed that an increase in the loading rate leads to an increase in the crack-initiation related term, while the crack-propagation related parameter decreases. This results in a non-monotonic trend of the specific work of fracture with the loading rate, providing valuable insights into the material's performance under various conditions.

Another significant development in toughened PA66 is the creation of polyamide-polyolefin nano-alloys. Itaru Natori's research explored the effect of an olefinic functionalized-oligomer, specifically hydrogenated polybutadiene with trimellitic anhydride groups, on the properties of PA66. The nano-alloys prepared from PA66 and this functionalized oligomer exhibited enhanced tensile strength and Izod impact strength, making them ideal for applications requiring high durability and resilience.

Furthermore, the blending process using a heat twin screw extruder was found to be effective in preparing these nano-alloys. The content of the functionalized oligomer significantly influenced the mechanical properties of the resulting material, allowing for tailored designs to meet specific application requirements.

In addition to rubber toughening and nano-alloying, other approaches are also being explored to further enhance the properties of PA66. For instance, the use of maleic anhydride grafted polyethylene-octene elastomer and nano-TiO2 as additives has shown promise in improving the low-temperature properties of toughened PA66. These additives not only enhance the material's toughness but also improve its resistance to cracking and wear.

Overall, the ongoing advancements in toughened PA66 are driving its adoption across various industries, including automotive, aerospace, and electronics. The combination of enhanced mechanical properties, durability, and tailored designs makes this material an excellent choice for applications requiring high performance and reliability.

As research and development continue, it is expected that new innovations in toughened PA66 will emerge, further expanding its potential applications and market reach. The materials science and engineering communities are closely monitoring these developments, eager to see how toughened PA66 will shape the future of advanced materials and technologies.

Copyright © 2024 Suzhou Accom New Material Technology Co., Ltd. All Rights Reserved.