One of the most significant advancements in toughened PPS is the incorporation of elastomers to improve its impact resistance and ductility. Traditional PPS, while robust, tends to be brittle and susceptible to cracking under stress. By blending PPS with olefinic elastomers or terpolymers, manufacturers have successfully developed elastomer-toughened PPS compositions that exhibit significantly higher notched Izod impact strength. These blends offer a balance of stiffness and toughness, making them ideal for applications that require both strength and durability.

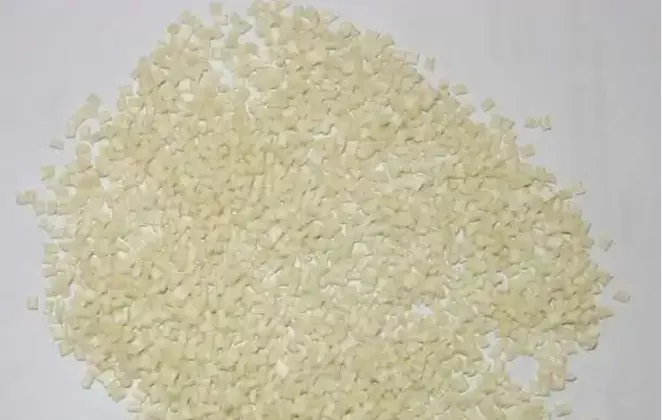

The toughening mechanism involves the dispersion of elastomer particles within the PPS matrix, which act as stress concentrators. Upon impact, these particles undergo deformation and dissipate energy, preventing crack propagation. Scanning electron microscope studies have revealed the finely dispersed elastomer particles within the PPS matrix, contributing to the enhanced impact resistance of the material.

Enhanced Thermal and Chemical Resistance

Toughened PPS retains the inherent thermal stability of virgin PPS, making it capable of withstanding high temperatures without degradation. It can be continuously used in air at temperatures up to 280°C and shows no signs of decomposition even when heated to 450-500°C. Chemically, PPS is resistant to a wide range of acids, bases, and solvents, with the notable exception of nitric acid. This makes it an excellent choice for applications in harsh environments where exposure to chemicals is a concern.

Expanding Application Scope

The enhanced properties of toughened PPS have broadened its application scope beyond traditional realms. In the automotive industry, for instance, elastomer-toughened PPS is finding use in under-the-hood components, fuel systems, and electrical parts due to its combination of heat resistance, chemical stability, and improved impact strength. Its lightweight and dimensional stability make it an attractive alternative to metals in these applications, contributing to fuel efficiency and reduced emissions.

In the electronics sector, toughened PPS is gaining popularity as a material for connectors, sockets, and other components due to its excellent electrical insulation properties and resistance to arc tracking. Its ability to withstand high temperatures makes it suitable for use in LED lighting and high-power electronics where heat dissipation is critical.

Moreover, the material's resistance to chemicals and high temperatures makes it ideal for use in chemical processing equipment, such as pumps, valves, and piping. Its corrosion resistance and ability to maintain mechanical properties at elevated temperatures make it a reliable choice for these demanding applications.

Innovations in Processing and Reinforcement

Advancements in processing techniques have further enhanced the versatility of toughened PPS. Reactive processing methods, for example, allow for the in-situ toughening of PPS by incorporating functionalized elastomers during melt processing. This eliminates the need for pretreatments, such as acid washing or hot water treatment, simplifying the manufacturing process and reducing costs.

Reinforcement of toughened PPS with glass fibers or carbon fibers further boosts its mechanical properties, such as tensile strength and stiffness. These reinforced composites are finding use in structural applications where high load-bearing capacity is required. The addition of fillers, such as talc or mica, can also improve the material's dimensional stability and thermal conductivity.

Environmental Considerations and Sustainability

As the global focus on sustainability intensifies, manufacturers of toughened PPS are increasingly exploring eco-friendly production methods and recyclable formulations. While PPS itself is resistant to biodegradation, efforts are underway to develop composites that incorporate biodegradable fillers or reinforcing agents. Additionally, recycling programs for PPS scrap and waste materials are being established to minimize environmental impact.

Regulatory Compliance and Standards

The use of toughened PPS in various industries is governed by a range of international standards and regulations. Compliance with standards such as those set by the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) is crucial for ensuring the safety and reliability of PPS-based products. Manufacturers must also adhere to environmental regulations, such as those related to the Restriction of Hazardous Substances (RoHS) and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH).

Future Prospects and Research Directions

The future of toughened PPS looks promising, with ongoing research focused on further enhancing its properties and exploring new applications. Efforts are underway to develop PPS composites with improved flame retardancy, conductivity, and tribological properties. Additionally, research into the use of PPS in 3D printing and additive manufacturing is gaining traction, opening up new possibilities for complex geometries and customized designs.

As the demand for high-performance materials continues to grow, the role of toughened PPS in meeting these demands will become increasingly important. With its combination of thermal stability, chemical resistance, and mechanical strength, toughened PPS is poised to play a pivotal role in driving innovations across various industries in the coming years.

Copyright © 2024 Suzhou Accom New Material Technology Co., Ltd. All Rights Reserved.