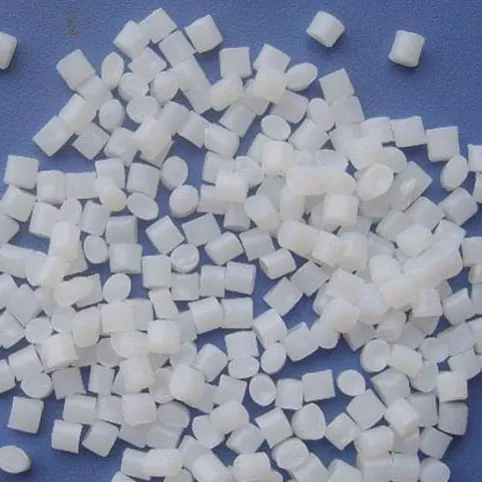

General plastic pellets are small, uniform pieces of plastic material that serve as the raw material for the production of a wide range of plastic products. But what exactly are they, and why are they so important in the manufacturing process? In this blog, we’ll explore the basics of general plastic pellets and their various applications in different industries.

General plastic pellets are made from a variety of plastic polymers, such as polyethylene, polypropylene, and polystyrene, among others. These pellets are created by melting plastic resin and then cooling it into small, bead-like shapes. They serve as the building blocks for the production of plastic products, and their composition can vary depending on the intended use of the final product.

Plastic pellets are incredibly versatile and easy to handle, which makes them a preferred choice in manufacturing. Their small, consistent size allows them to be easily transported and processed by machines such as injection molding, extrusion, and blow molding machines. Their uniformity also ensures a consistent quality of the final product, making them ideal for industries where precision is key.

General plastic pellets are used in a wide range of industries. Some of the most common applications include:

1. Packaging: Plastic pellets are commonly used to produce packaging materials, such as bottles, containers, and films.

2. Consumer Goods: Many everyday products, including toys, household items, and electronics, are made from plastic pellets.

3. Automotive Parts: Plastic pellets are used to produce various automotive components, including dashboards, bumpers, and interior panels.

4. Medical Devices: In the medical industry, plastic pellets are used to manufacture devices such as syringes, IV bags, and diagnostic equipment.

5. Construction Materials: Some types of plastic pellets are used in the production of durable building materials like pipes, insulation, and flooring.

The quality of the plastic pellets used in manufacturing directly affects the quality of the final product. High-quality pellets ensure consistent performance, better durability, and improved processing efficiency. Low-quality pellets, on the other hand, can lead to defects, such as inconsistent shapes, poor finishing, and weak structural integrity in the final product. Therefore, it’s important to source pellets from reliable suppliers who prioritize quality.

Once the plastic pellets are delivered to a manufacturing facility, they are typically melted down and shaped into the desired product through various processing techniques, such as injection molding, extrusion, or blow molding. The process may also involve the addition of colorants, additives, or reinforcing agents to achieve specific material properties, such as strength, flexibility, or resistance to heat.

If you're looking to purchase high-quality general plastic pellets, look no further than www.accom-material.com. Our website offers a wide range of plastic pellets that are perfect for various manufacturing needs. Whether you’re in the packaging, automotive, medical, or construction industry, we have the materials to meet your specifications. Visit us today to explore our products and place your order for high-quality general plastic pellets.

www.accom-material.com — Visit us now to get the best plastic pellets for your manufacturing needs!

Copyright © 2024 Suzhou Accom New Material Technology Co., Ltd. All Rights Reserved.